Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

Flexographic printing uses flexible relief plates to put ink on different materials. Many companies use flexographic printing for packaging. It is very common for flexible packaging and labels. Flexible packaging is the biggest part of global packaging. It makes up more than 44%. Flexo printing is the main way to print on flexible packaging. Corrugated packaging, folding cartons, and labels also use flexographic methods. These methods help with branding and product details. New flexo printing machines from Huabo help companies print packaging fast. They also make printing efficient and high-quality.

Industry Segment | Role in Flexographic Printing | Market Share / Growth Details |

|---|---|---|

Corrugated Packaging | Prints directly for shipping and branding | Has the largest market share |

Flexible Packaging | Used for food, drinks, and medicine | Grows the fastest |

Labels | Important for branding and product info | Is a key segment |

Flexographic printing uses soft plates to print clear pictures fast. It works on many things like paper, plastic, and films. Modern flexo machines print quickly and use less material. They can print in many colors. This makes them great for big packaging jobs. Flexo printing works with many types of ink and surfaces. It can use eco-friendly water-based inks for things that soak up liquid. This way of printing is fast and gives good quality. It is flexible and helps companies finish work on time. It also helps cut down on waste. Flexographic printing is best for printing lots of copies. Digital printing is better for small jobs and quick changes in design.

Flexographic printing uses a flexible plate to put ink on many surfaces. This method is good for packaging and labels. It prints fast and looks sharp. Flexo printing can work on porous and non-porous materials.

The flexographic printing process has several steps:

Plate Creation: Technicians make plates from rubber or photopolymer. Each plate is for one color, like cyan, magenta, yellow, or black. Sometimes, they add spot colors or varnishes for special looks.

Plate Mounting: Workers put each plate on a cylinder in the press. They line up the plates so colors match.

Ink Application: The press uses ink chambers and rollers. An anilox roller controls the ink amount. A doctor blade wipes off extra ink.

Substrate Feeding: The press moves the substrate, like paper or plastic film, through the machine. Tension controls keep it moving smoothly.

Printing and Image Transfer: The inked plate presses onto the substrate. The image goes onto the material with even pressure.

Drying or Curing: The printed substrate goes through a drying system. The system uses air, heat, infrared, or UV light to dry the ink.

Tip: Flexographic printing plates are quicker and cheaper to make than gravure cylinders. This helps companies save time and money for big print jobs.

Flexographic printing works with many ink types. Water-based inks are best for paper and cardboard. Solvent-based inks stick to plastic films and foils. UV-curable inks dry fast under UV light and work on non-porous surfaces. Electron beam inks cure quickly and are safe for food packaging.

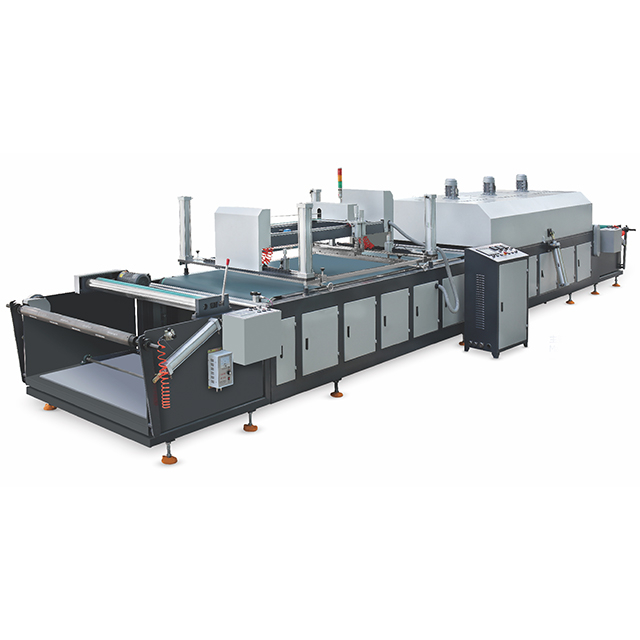

Modern flexo printing equipment makes printing fast and reliable. Huabo's Flexo Printing Machine has advanced features. It prints at high speed and quality. The machine can print many colors with up to ten decks. It prints on paper, plastic films, nonwoven materials, and paper cups. Automatic tension and registration controls keep prints sharp and clear.

Specification | Details |

|---|---|

Max. Web Width | 650mm to 1250mm (varies by model) |

Max. Printing Width | 560mm to 1160mm (varies by model) |

Max. Printing Speed | 100 m/min |

Ink Type | Water-based or solvent ink |

Substrates Supported | Films, Paper, Non-Woven, Paper Cups |

Color Printing Decks | 4, 6, 8, or 10 |

Drying System | Electric, Gas, Steam, Hot Oil |

Huabo's Flexo Printing Machine matches colors and registration well. The YT Series prints up to four colors at 60 meters per minute. The HB1200 model prints on nonwoven bags and medical fabrics at 20 meters per minute. These machines print on nonwoven fabrics (PP), polyethylene (PE), polypropylene (PP) films, roll paper, and laminated materials.

Model | Printing Type | Max Print Speed (m/min) | Substrates Supported |

|---|---|---|---|

HB1200 | Roll-to-Roll Screen | Up to 20 | Nonwoven bags, medical fabrics |

YT Series | Flexographic | Up to 60 | Nonwoven, PE, PP bags |

Flexo presses use anilox rollers to control ink flow. This stops ink splatter during fast printing. Drying systems with adjustable heat help fix the ink quickly. Both Huabo machines print on both sides and in many colors. This makes them great for packaging.

Flexographic printing works with many substrates. Common ones are paper, paperboard, plastic films, foils, and corrugated board. Water-based inks are good for porous substrates like paper and cardboard. Solvent-based and UV-curable inks work best for non-porous substrates like plastic films and foils. Flexo printing machines from Huabo work well with nonwoven fabrics, PE, PP, and other flexible materials.

Ink Type | Typical Substrates | Drying Method | Notes |

|---|---|---|---|

Water-based | Paper, cardboard, corrugated board | Evaporation | Eco-friendly, best for porous substrates |

Solvent-based | Plastic films, foils | Evaporation | Fast drying, good for non-porous substrates |

UV-curable | Shrink sleeves, folding cartons | UV light | Instant curing, high color strength |

Electron Beam | Flexible packaging | Electron beam | Rapid curing, food safe |

Narrow-web flexographic printing is used for labels and small packaging. It uses smaller presses and narrow rolls of substrate. Flexo printing is a top choice for packaging because it is fast, flexible, and gives high print quality.

Flexographic printing is known for being fast and efficient. Companies use flexo presses to finish big print jobs quickly. New flexo machines, like those from Huabo, have automatic systems. These systems help save time and cut down on wasted materials. Workers can switch jobs faster, so businesses meet tight deadlines.

Automation in flexo printing saves money on workers and boosts output. Servo-driven presses can cut setup time in half. Less than half as much material is wasted during setup. LED-UV drying uses less energy and helps save power.

Cost Factor | Impact/Reduction |

|---|---|

Substrate waste | Cut by more than 50% during setup |

Setup time | Cut by up to 50% with servo-driven presses |

Energy consumption | Lowered by using energy-saving technology |

Labor costs | Lowered by using automation |

Consumables (ink, plates) | New presses use less ink and plates |

ROI timeline | Full ROI from servo upgrade in about 14 months |

Huabo Flexo Printing Machine prints fast and gives steady results. The controls are simple, so workers learn quickly. The machine prints up to 60 meters each minute. This makes it a good choice for big packaging jobs. Flexo printing lets companies make bright images and full-color prints with less waiting.

Flexo printing cuts reprint times from days to just hours.

Companies use eco-friendly materials and water-based inks without extra cost.

New flexo plates and automation help lower waste and speed up job changes.

Flexographic printing makes sharp images and bright colors. Flexo presses use photopolymer plates for clear pictures and even color. Flexo printing can reach 300 to 600 dpi, which helps match colors well, even Pantone colors. This process is still a good deal for big print jobs.

Printing Method | Resolution (dpi) | Color Consistency and Quality Characteristics |

|---|---|---|

Flexographic | 300 - 600 | Good color matching, steady results, good for big jobs, a little less color detail than offset and digital |

Offset | Up to 1200 | Best resolution, great color control, more detail |

Digital | 600 - 1000 | Higher resolution, better color, sharper text, best for custom jobs |

Flexo printing works on many materials and uses different inks. Workers print on paper, plastic, foil, cardboard, and flexible packages. Flexo presses can handle many shapes, sizes, and textures. The process uses solvent, water, and UV-cured inks that dry fast and fit many uses.

Flexo printing works on bumpy surfaces because of flexible plates.

Companies print labels, food packages, newspapers, and wallpaper with flexo presses.

Water-based inks are better for the environment.

Flexo printing is still a smart choice for big print runs.

Huabo Flexo Printing Machine can print on nonwoven fabrics, PE, PP, and laminated stuff. Workers get great print results on many bag types and packages. The machine prints fast and keeps colors even.

Flexographic printing is important for packaging in many businesses. Companies use flexographic presses to make boxes, bags, and labels. Retail stores need flexographic printing for displays and shipping boxes. Food companies use flexographic printing for ice cream, cheese, meats, soups, and snacks. Flexographic printing also makes tamper-evident bands and shrink labels for safety.

Flexographic printing uses flexible plates to make clear images. This process is fast and good for big packaging jobs.

Manufacturers pick flexographic printing for pouches, liners, and wraps. They also use it for labels and special packaging. Flexographic printing helps with branding and product details on labels. Retail and promotional companies like flexographic printing for its speed and quality.

Packaging Product Category | Examples of Packaging Products and Substrates Used in Flexographic Printing |

|---|---|

Flexible Packaging Forms | Bags, pouches, labels, liners, wraps |

Food Packaging | Ice cream, cheese, packaged meats, soups, sauces, spices, produce, nutraceuticals, pet food |

Tamper-evident and Shrink Labels | Tamper-evident bands, shrink-label stock |

Product Display Materials | Flat-pack cardboard displays, point-of-purchase marketing materials |

Common Substrates | Polypropylene (PP), Polyester (PET), Polyamide (Nylon), Cellophane, PVC, Polyethylene (PE) films |

Flexographic machines from Huabo print on many materials. These machines print on nonwoven bags, PE bags, PP bags, and more. Flexographic presses use photopolymer plates and water or solvent inks for bright colors. The machines print fast and have controls for steady results.

Manufacturers use flexographic printing for T-shirt bags, D-cut bags, vest bags, gift bags, and pre-made bags. Flexographic presses work well with PE and PP films, paper rolls, and laminated materials. Some machines print on both sides and use corona treatment for better ink on PP bags.

Stack type flexographic machines print on PE and PP bags. These machines are simple and easy to fix.

Central impression flexographic machines print with high accuracy. They are best for thin films and high-quality packaging.

Flexographic printing works for many packaging types and labels. Companies use flexographic presses for packaging that needs bright colors and strong images. Flexographic printing helps businesses make packaging and labels that look great in stores.

Flexographic printing and offset printing are both used for packaging. Flexographic printing uses flexible plates and inks that dry fast. Offset printing uses a more detailed ink transfer system. Flexographic presses are quick to set up and run fast. This makes them good for big packaging jobs. Offset presses need more time to set up but make very high-quality prints.

Aspect | Flexographic Printing | Offset Printing |

|---|---|---|

Production Speed | Faster because of simple ink systems and quick-drying inks | Slower because of complex ink systems and longer drying times |

Flexographic printing is great for long jobs. It spreads setup costs over many items. Offset printing is better for short or medium jobs when print quality matters most. Flexographic presses can print on many materials like plastic films, coated linerboard, and foil. Offset presses mostly print on paper and cardboard.

Flexographic printing works with:

Plastic films like PVC, polyethylene, polyester, polypropylene, polystyrene, cellophane

Metal-coated films

Synthetic papers

Corrugated board and wax paper

Offset printing inks work best on materials that soak up ink. Flexographic inks stick to both absorbent and non-absorbent surfaces. This makes flexographic printing more useful for packaging.

Digital printing has changed how companies make packaging. Digital presses do not need plates. They can start printing right away. This saves time for short jobs and custom orders. Flexographic printing needs plates and setup, so it is best for big jobs.

Aspect | Flexographic Printing | Digital Printing |

|---|---|---|

Setup Time | Needs plate setup first; can take days for complex designs. | No plate setup needed; printing starts right away. |

Run Speed | Very fast for big jobs after setup is done. | Fast and getting better with new technology. |

Suitability | Best for big jobs because setup time and cost are spread out. | Great for short jobs, quick changes, many SKUs, and on-demand printing. |

Flexibility | Not flexible after plates are made; changes need new plates. | Very flexible; allows quick changes and variable data. |

Digital printing is quick and can print different designs easily. It is perfect for personalized packaging. Flexographic printing is still the best for fast, low-cost printing of lots of packaging. Digital printing costs less for short jobs but gets expensive for big jobs because of ink and finishing costs.

Flexographic printing is fast, works on many materials, and saves money for big packaging jobs. Digital printing is flexible and good for quick changes, but flexographic printing is best for making lots of packages.

Flexographic printing is fast and gives good results. It helps packaging companies save money. Businesses get many benefits:

Jobs finish quickly and machines print fast

Works on lots of materials and package styles

Water-based inks are better for the environment

Prints look clear and sharp every time

New machines from Huabo work well and are dependable. Companies should use automation and train workers. They need to pick the right equipment for their packaging jobs to get the best results.

Flexographic printing machines work with nonwoven fabrics, PE, PP films, paper rolls, and laminated materials. These machines print on many bags, packaging, and labels.

Modern flexographic printing machines can go up to 60 meters each minute. Some models print as many as 3,500 bags every hour. Fast printing helps businesses finish big orders quickly.

Flexographic printing machines can print in many colors. The YT Series from Huabo prints up to four colors. This lets companies make bright packaging and detailed designs.

Most flexographic printing machines have simple controls. Operators learn how to use them quickly. Automatic systems help cut setup time and lower mistakes.

Flexographic printing machines print on T-shirt bags, D-cut bags, vest bags, gift bags, and pre-made bags. These machines work well for retail, promotional, and food packaging.