Views: 0 Author: Site Editor Publish Time: 2026-01-06 Origin: Site

As the world increasingly prioritizes sustainability, non-woven bags are gaining popularity. These eco-friendly alternatives are becoming a staple in retail, packaging, and promotional industries. The rise in demand calls for businesses to adopt Non Woven Bag Making Machines to meet these market needs.

In this article, we’ll explore the current position of Non Woven Bag Making Machines in the market and discuss their potential for growth. We’ll cover key trends, innovations, and challenges that businesses must navigate to stay competitive.

The global push towards sustainability is driving an increasing demand for eco-friendly packaging solutions. Non-woven bags are a significant part of this trend, as they are reusable, recyclable, and biodegradable. As governments implement regulations to curb single-use plastics, businesses are turning to non-woven bags to meet consumer demand for environmentally responsible packaging. This shift is not only driven by regulations but also by rising consumer awareness of plastic pollution and the environmental impact of disposable packaging.

The market for non-woven bags is projected to grow rapidly, and this trend is expected to continue as more industries adopt these bags as sustainable alternatives to plastic. As a result, the demand for Non Woven Bag Making Machines that can efficiently produce high volumes of these eco-friendly bags is expected to surge.

Consumers are increasingly seeking brands that offer sustainable, reusable, and eco-friendly packaging. Non-woven bags are well-positioned to meet this demand due to their durability and ability to be used multiple times. This consumer preference is driving more businesses, especially in retail, food packaging, and promotional industries, to adopt Non Woven Bag Making Machines for in-house production of these bags.

The versatility of non-woven bags, with options for custom prints, handle types, and various sizes, further contributes to their growing popularity. These bags not only align with environmental concerns but also serve as effective marketing tools, helping businesses to promote their brand sustainably.

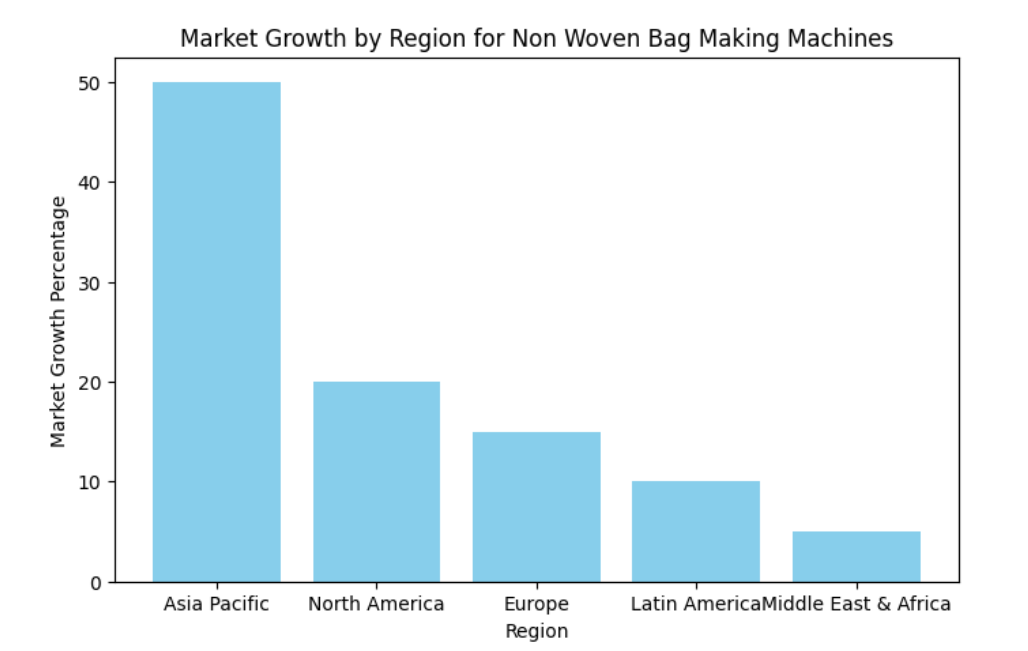

The demand for non-woven bags is not limited to developed regions. Emerging markets, especially in Asia Pacific and Latin America, are seeing rapid adoption of these bags as both consumers and governments prioritize sustainable packaging. As such, the demand for Non Woven Bag Making Machines is expanding globally, driven by technological advancements that make the production process more efficient and cost-effective.

Technologies like automation, smart sensors, and IoT integration are enabling manufacturers to produce bags more efficiently, reducing costs and waste, and improving the overall quality of non-woven bags. These advancements are vital for meeting the growing demand in both developed and emerging markets.

The introduction of automation in Non Woven Bag Making Machines has revolutionized the production process. Automated systems allow businesses to produce non-woven bags at much higher speeds while minimizing human labor. Fully automated machines are now capable of producing hundreds of bags per minute, reducing production costs and increasing throughput.

Integration of AI and IoT technologies further enhances the efficiency of these machines. AI allows for predictive maintenance, while IoT enables remote monitoring and optimization of the production process. These advancements ensure that Non Woven Bag Making Machines operate at peak efficiency, improving production times and reducing downtime.

Modern Non Woven Bag Making Machines offer a high degree of customization, enabling businesses to meet diverse market demands. Machines can now produce a wide range of bag designs, including D-cut bags, loop-handle bags, and T-shirt bags, all with customizable prints, colors, and sizes. This versatility makes these machines suitable for various industries, including retail, food packaging, and promotional use.

As consumer demand for personalized and branded products rises, the ability to customize non-woven bags becomes an essential feature for manufacturers. By investing in machines that allow for easy customization, businesses can stay competitive and meet the evolving needs of their customers.

Bag Type | Machine Type | Customization Features |

D-Cut Bags | Semi-Automatic or Fully Automatic | Handle types, printing options |

Loop Handle Bags | Fully Automatic | Custom designs, strong handles, printing |

T-Shirt Bags | Fully Automatic | High-speed production, large size options |

Shopping Bags | Fully Automatic | Custom size and print designs, eco-material |

In line with the global focus on sustainability, many Non Woven Bag Making Machines are being designed to be energy-efficient. These machines reduce energy consumption, which helps businesses lower their operational costs and reduce their carbon footprint. Some machines are even designed with energy-saving features, such as automatic shutdowns and low-power modes, ensuring that they meet sustainability goals while delivering high productivity.

As the demand for eco-friendly production methods continues to grow, investing in energy-efficient Non Woven Bag Making Machines can help businesses align with global sustainability trends and attract environmentally-conscious consumers.

The Non Woven Bag Making Machine market is poised for significant growth in the coming years. The market size was valued at approximately $2.5 billion in 2024 and is expected to grow at a CAGR of 7.2% over the next decade. The growing demand for non-woven bags, driven by sustainability trends and regulations, presents a major opportunity for machine manufacturers.

Additionally, as non-woven bags become more widely adopted across industries, manufacturers of Non Woven Bag Making Machines will see an increase in demand for their products, driving market expansion.

When choosing a Non Woven Bag Making Machine, businesses need to consider their production scale and budget. Semi-automatic machines are typically more affordable and suitable for small to medium-sized businesses with lower production volumes. They offer flexibility in production but require more manual labor.

On the other hand, fully automatic machines are designed for large-scale production and offer faster speeds, higher production capacity, and lower labor costs. However, they come at a higher initial investment. For businesses with high-volume production needs, fully automatic machines offer better long-term savings and higher ROI.

Feature | Semi-Automatic Machines | Fully Automatic Machines |

Initial Cost | Lower | Higher |

Production Speed | Medium (up to 100 bags/min) | High (up to 220 bags/min) |

Labor Costs | More workers needed | Fewer workers needed |

Maintenance | Easier and cheaper | Harder, potentially higher maintenance |

Investing in Non Woven Bag Making Machines provides several economic advantages. The automation of production processes reduces labor costs, while high-efficiency machines reduce material waste and energy consumption. As a result, businesses that invest in these machines see significant improvements in operational efficiency, faster production times, and better overall profitability.

For businesses looking to maximize their ROI, investing in modern, energy-efficient, and customizable machines will ensure they can meet growing demand while staying competitive.

One of the major barriers for small businesses looking to invest in Non Woven Bag Making Machines is the high initial cost of fully automatic machines. However, financing options, leasing models, and government subsidies for sustainable businesses are helping small and medium enterprises (SMEs) overcome this challenge. Choosing semi-automatic machines or more affordable models can also provide a cost-effective solution without sacrificing production efficiency.

As consumer demand for unique, customized packaging grows, businesses are increasingly seeking machines that can offer high-quality, custom-designed non-woven bags. The flexibility of Non Woven Bag Making Machines allows businesses to adapt to varying market demands, producing bags with different sizes, designs, and features. Businesses that invest in versatile machines can capitalize on this demand for customization.

Government regulations, particularly around sustainability and the reduction of plastic waste, are both a challenge and an opportunity. As more regions introduce stringent environmental regulations, businesses must comply by shifting to eco-friendly packaging options like non-woven bags. Non Woven Bag Making Machines that can efficiently produce sustainable bags will be in high demand as businesses seek ways to comply with these regulations.

Leading manufacturers in the Non Woven Bag Making Machine market include companies such as Oyang Group, ZXL Machinery, and KETE Machinery. These companies are recognized for their innovation, quality, and global market presence. By focusing on research and development, they continue to introduce new technologies to enhance machine performance and meet evolving customer demands.

Manufacturers like Oyang Group and ZXL Machinery are driving innovations in automation, machine speed, and customization. The integration of smart features, such as real-time monitoring and AI-driven predictive maintenance, has allowed these manufacturers to stay ahead of the competition while offering high-quality, efficient solutions.

Strategic partnerships between machine manufacturers, raw material suppliers, and environmental agencies are helping promote sustainability in the industry. These collaborations allow manufacturers to incorporate eco-friendly materials into their machines, improving their market position and fostering innovation in sustainable production methods.

The Non Woven Bag Making Machine market is set for continued growth, with projections showing a steady increase in demand driven by both sustainability initiatives and the ongoing need for eco-friendly packaging solutions. Manufacturers will need to keep pace with demand by developing machines that are faster, more efficient, and environmentally friendly.

Technological innovations, particularly in automation, AI, and IoT, will continue to shape the future of Non Woven Bag Making Machines. Advances in machine intelligence will allow for faster production, better quality control, and reduced waste, making these machines even more attractive to businesses in the long term.

To stay competitive, manufacturers should continue to innovate and invest in energy-efficient, customizable machines. Businesses should prioritize Non Woven Bag Making Machines that offer high efficiency, scalability, and the ability to meet consumer demand for eco-friendly products.

The Non Woven Bag Making Machine market is experiencing significant growth, fueled by sustainability trends and technological advancements. With rising consumer demand for eco-friendly packaging, businesses investing in high-efficiency, customizable, and energy-efficient machines will have a competitive edge. Companies like Wenzhou Huabo Plastic Packaging Machinery Co., Ltd. offer innovative solutions that help businesses meet market demands while promoting sustainability. These machines enable companies to stay ahead in a rapidly changing industry.

A: A Non Woven Bag Making Machine is specialized equipment used to produce eco-friendly, durable bags from non-woven fabric. It performs tasks like cutting, sealing, and folding to create high-quality bags.

A: The increasing demand for eco-friendly packaging, government regulations, and consumer preference for reusable bags are driving the need for Non Woven Bag Making Machines in various industries.

A: Non Woven Bag Making Machines help reduce plastic waste by producing reusable, biodegradable bags, offering a more sustainable alternative to traditional plastic packaging.

A: Investing in a Non Woven Bag Making Machine improves efficiency, lowers labor costs, and allows for the production of customizable, eco-friendly bags, making it a valuable asset for businesses.

A: The price of a Non Woven Bag Making Machine varies based on features, automation level, and production capacity, with costs typically ranging from $5,000 to $50,000.